Welcome to this site!Shanghai Univerwave Co.,Ltd

www.univerwave.cn 丨HV Testing

Technology create the future

Let us work together

Why corona ring on compound insulator cannot be reversed installed?

Source:

|

Author:佚名

|

Published time: 2021-03-04

|

185 Views

|

Share:

Silicone rubber composite insulator is generally composed of two or more organic materials.Compared to electric porcelain insulator,it has the advantages of light weight, high strength (mandrel), impact resistance, high pollution lightning voltage, easy installation, no need to measure zero, lightning strike, pollution flash will not occur insulation breakdown, etc.

Silicone rubber composite insulator is generally composed of two or more organic materials.Compared to electric porcelain insulator,it has the advantages of light weight, high strength (mandrel), impact resistance, high pollution lightning voltage, easy installation, no need to measure zero, lightning strike, pollution flash will not occur insulation breakdown, etc.Composite insulator is composed of mandrel, sheath, umbrella skirt, end fittings and accessories. It is the first choice for heavy pollution area.

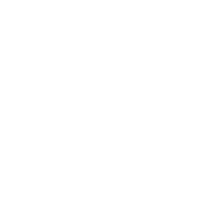

The composite insulator is in the extremely uneven electric field in the ultra-high voltage line.There is only a short distance near the wire at the high field strength position,the long insulation string in the middle is located at a relatively low electric field, so it is necessary to install a corona ring on both ends to improve the distributed voltage of the insulator string, to protect the silicon rubber skirt from being burned by the arc in the case of over voltage short circuit and flash over, and to protect the connection of both ends of mandrels and metal fittings from the damage of sealing performance due to leakage marks and electrical erosion.The interface between the metal, the mandrel, the sheath and other materials is the most dangerous interface of the composite insulator.There are many kinds of materials at the interface, and the electric field intensity is high. The air at the interface is prone to ionization, which leads to dendritic discharge of silicone rubber and electric corrosion of silicone rubber sheath, resulting in direct contact with the atmosphere.

Under the action of electric field, corona is generated, which makes nitrogen in the air react with oxygen to produce nitrous anhydride, and then react with water vapor to generate nitrous acid, which corrodes the mandrel and causes brittle break of composite insulators, leading to major accidents of line dropping.In addition, corona discharge is easily generated near the metal port at high field intensity.It can make the sheath with silicone rubber as the main material undergo corona ablation for a long time, and the hydrophobicity is weakened until it disappears.

Although the corona ring can improve the overall distributed voltage of the composite insulator, its effect is not as uniform as that of the disk-shaped insulator string, but it can obviously reduce the field intensity at the connection between the mandrel and metal fitting.The improvement of field strength is related to the selection of appropriate outer diameter and pipe diameter of corona ring.(The experimental results show that the larger the diameter R of the high voltage end corona ring is, the lower the end field strength and average field strength at the ring side. When R > 10mm, the end field intensity can be reduced to below the air breakdown field intensity (3.0kV/cm). If the radius R of the corona ring is too small, the field strength will increase at 10% of the insulation distance from the high voltage side. The larger the radius R of the corona ring is, the lower the average field strength and the more uniform the electric field distribution will be. Therefore, 250mm ~ 300mm is recommended for the radius R of the corona ring at the high voltage end of 500kV.)

It also has a great relationship with the distance of the corona ring deep into (raised) the umbrella skirt.When the depth distance of the corona ring Δh≈0,the joint of mandrel and metal at the open plane of the corona ring will bear the maximum field strength,if it exceeds the air breakdown field strength (3.0kV/cm), a serious corona discharge will occur.This kind of concentrated electric field will make the micro pores, material defects or different interfaces in the silicone rubber material produce leakage marks,that is to say,25% ~ 30% of the operating voltage should be sustained on the insulator string of about 6% length,which accelerates the aging of the mandrel and the sealing performance of the silicone rubber sheath is damaged due to electrical erosion and perforation, leading to the string breaking accident of the composite insulator mandrel.

In addition, during line construction and project completion acceptance, the vast majority of units do not conduct acceptance according to the depth size of composite insulator corona rings.It is generally adopted to visually observe whether the openings of the upper and lower corona rings of composite insulators are aligned to check the entire installation quality. Because some employees are not clear about the principle of corona ring, the reversed installation has been found in the project. When the corona ring on the high voltage side of the composite insulator is correctly installed, the field strength at the end of the metal fitting is 14.12kV/cm, and when inverted, it is 30.79kV /cm.

It shows that the correct installation of coronal ring has great influence on the electrical properties of composite insulators.When some units replace the original design of hanging double-string disc type antifouling glass insulator string with composite insulator,the corona ring of the disc type double string was not replaced at the same time, thus, less than one year after the replacement, the brittle fracture accident of the newly replaced composite insulator mandrel occurred again.

The composite insulator is in the extremely uneven electric field in the ultra-high voltage line.There is only a short distance near the wire at the high field strength position,the long insulation string in the middle is located at a relatively low electric field, so it is necessary to install a corona ring on both ends to improve the distributed voltage of the insulator string, to protect the silicon rubber skirt from being burned by the arc in the case of over voltage short circuit and flash over, and to protect the connection of both ends of mandrels and metal fittings from the damage of sealing performance due to leakage marks and electrical erosion.The interface between the metal, the mandrel, the sheath and other materials is the most dangerous interface of the composite insulator.There are many kinds of materials at the interface, and the electric field intensity is high. The air at the interface is prone to ionization, which leads to dendritic discharge of silicone rubber and electric corrosion of silicone rubber sheath, resulting in direct contact with the atmosphere.

Under the action of electric field, corona is generated, which makes nitrogen in the air react with oxygen to produce nitrous anhydride, and then react with water vapor to generate nitrous acid, which corrodes the mandrel and causes brittle break of composite insulators, leading to major accidents of line dropping.In addition, corona discharge is easily generated near the metal port at high field intensity.It can make the sheath with silicone rubber as the main material undergo corona ablation for a long time, and the hydrophobicity is weakened until it disappears.

Although the corona ring can improve the overall distributed voltage of the composite insulator, its effect is not as uniform as that of the disk-shaped insulator string, but it can obviously reduce the field intensity at the connection between the mandrel and metal fitting.The improvement of field strength is related to the selection of appropriate outer diameter and pipe diameter of corona ring.(The experimental results show that the larger the diameter R of the high voltage end corona ring is, the lower the end field strength and average field strength at the ring side. When R > 10mm, the end field intensity can be reduced to below the air breakdown field intensity (3.0kV/cm). If the radius R of the corona ring is too small, the field strength will increase at 10% of the insulation distance from the high voltage side. The larger the radius R of the corona ring is, the lower the average field strength and the more uniform the electric field distribution will be. Therefore, 250mm ~ 300mm is recommended for the radius R of the corona ring at the high voltage end of 500kV.)

It also has a great relationship with the distance of the corona ring deep into (raised) the umbrella skirt.When the depth distance of the corona ring Δh≈0,the joint of mandrel and metal at the open plane of the corona ring will bear the maximum field strength,if it exceeds the air breakdown field strength (3.0kV/cm), a serious corona discharge will occur.This kind of concentrated electric field will make the micro pores, material defects or different interfaces in the silicone rubber material produce leakage marks,that is to say,25% ~ 30% of the operating voltage should be sustained on the insulator string of about 6% length,which accelerates the aging of the mandrel and the sealing performance of the silicone rubber sheath is damaged due to electrical erosion and perforation, leading to the string breaking accident of the composite insulator mandrel.

In addition, during line construction and project completion acceptance, the vast majority of units do not conduct acceptance according to the depth size of composite insulator corona rings.It is generally adopted to visually observe whether the openings of the upper and lower corona rings of composite insulators are aligned to check the entire installation quality. Because some employees are not clear about the principle of corona ring, the reversed installation has been found in the project. When the corona ring on the high voltage side of the composite insulator is correctly installed, the field strength at the end of the metal fitting is 14.12kV/cm, and when inverted, it is 30.79kV /cm.

It shows that the correct installation of coronal ring has great influence on the electrical properties of composite insulators.When some units replace the original design of hanging double-string disc type antifouling glass insulator string with composite insulator,the corona ring of the disc type double string was not replaced at the same time, thus, less than one year after the replacement, the brittle fracture accident of the newly replaced composite insulator mandrel occurred again.

Next:

None

Applications

Functions

www.univerwave.cn 丨 HV Testing

Mob: +86 137 9543 5491 Email:info@univerwave.cn

Add: First Floor,Building 2,No.1876,Road Chenqiao,Fengxian District,Shanghai